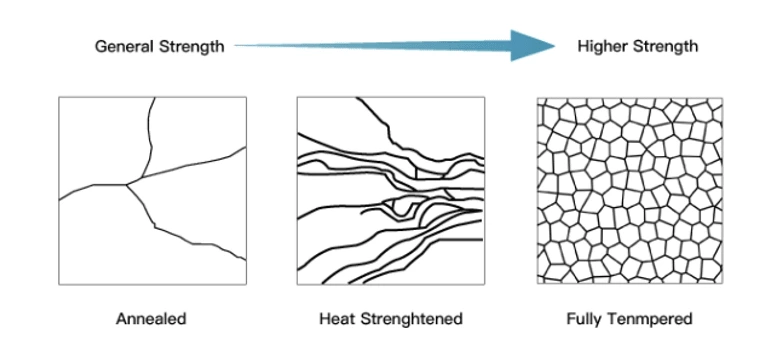

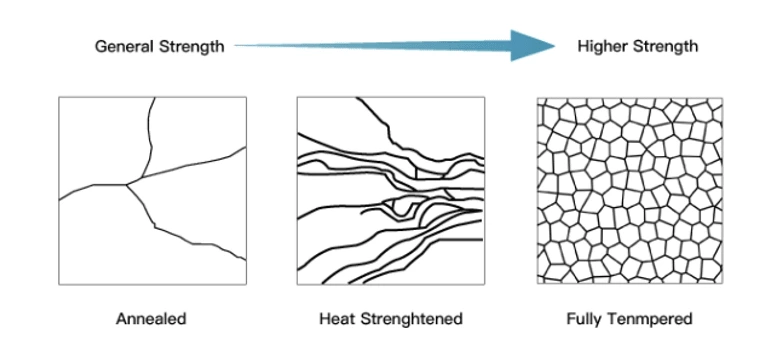

Tempered glass also called as toughened glass, tuffen glass, hardened glass, ESG glass, it is a type of glass that is processed with thermal treatments, which increase its strength. The process of tempering leaves the outer surface of glass in a state of compression, and the interior in a state of tension.

Tempering process is a thermal process which put the grinded anneal glass to the temper machine with heating to about 700 degrees maintaining a while and then cool down rapidly by a strong wind jet. Causing the outer surface into compression and the inner side still in tension.And ordinary glass when they break, will present large pieces of sharp corners. It is easy to cause injuries to people.

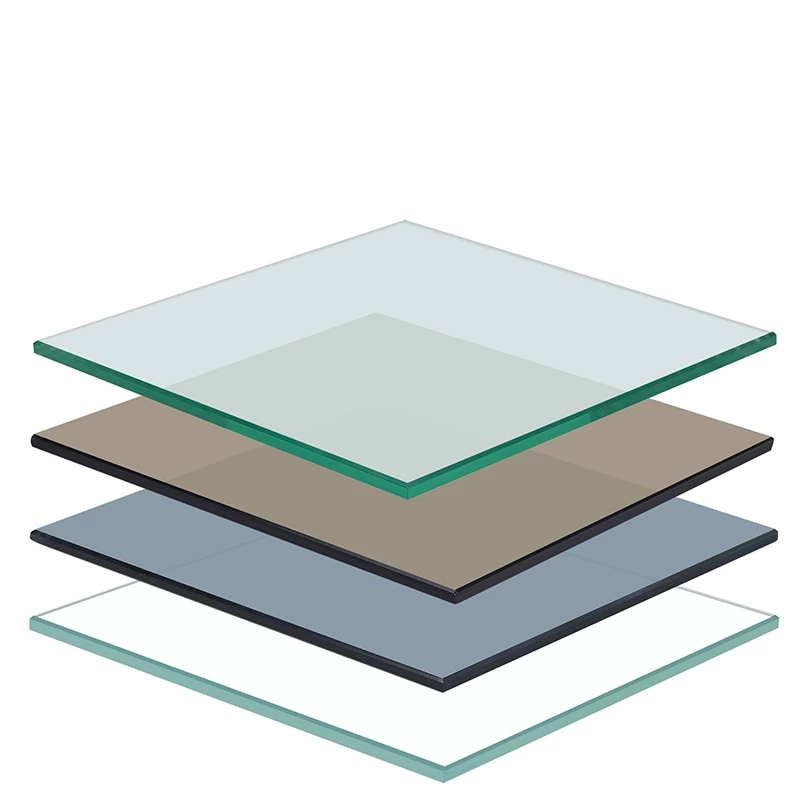

In the field of windows and doors, toughened glass, in addition to single-layer independent use, can also be combined through the hollowing process, laminated technology. This way the production of tempered window glass, can have strength, can both sound insulation, energy saving, safety and other characteristics. At the same time, Xinlian uses the highest quality and purity of raw materials in the industry to produce products that are far lower than the peers' self-explosion rate while improving the flatness, and provides up to 5 years of warranty.

Advantages:

The glass strength increase 5 times more and making the glass safe because even when the tempered glass is broken, the glass will shatter into small pieces with obtuse angles which will do no harm to human beings.If you are interested in our product, please feel free to discuss with us.

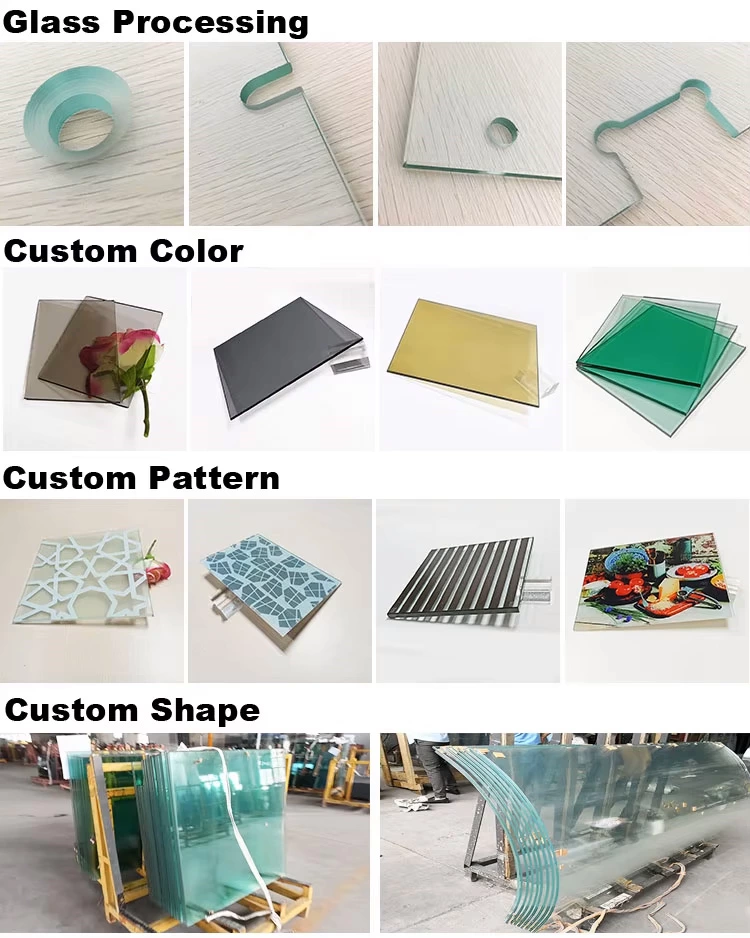

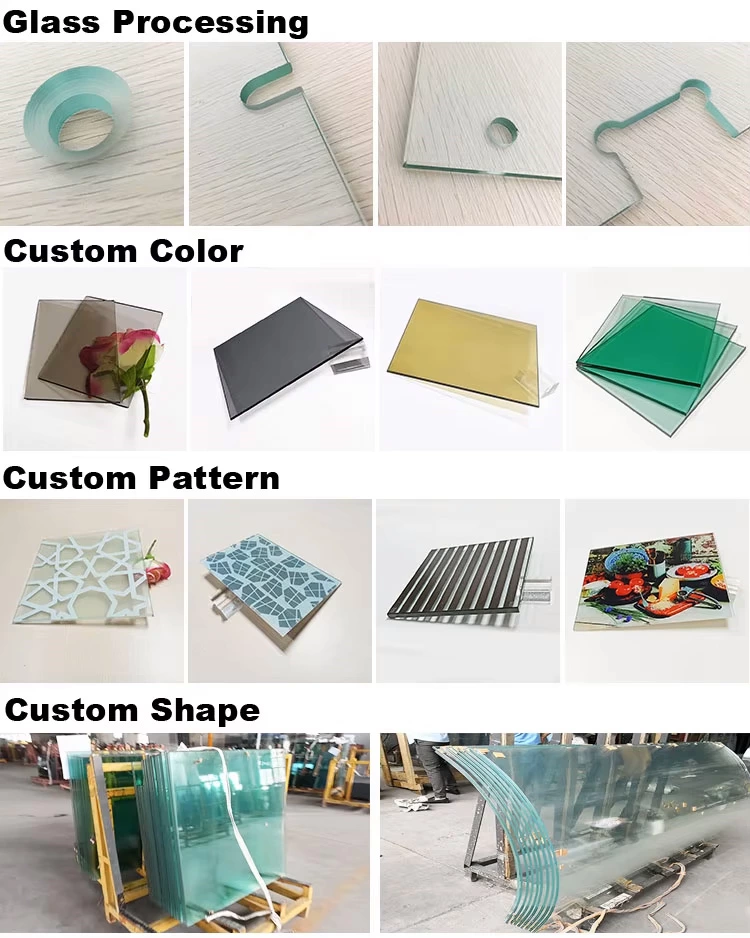

Custom service:

The custom service can provide different glass processing method, color custom,pattern custom and shape custom. If you want to know more about different custom method, please share with us.

Glass processing(holes drilling, cutouts)

Application:

- Window & Door

- Railing/Balustrade/Handrail

- Shower door

- Partiton Wall

- Canopy/Awning

- Furniture

FAQ

Q1: How can I order and get an accurate quotation?

A1:This will depend on the scenario in which you use it, the climatic characteristics of your environment, and what level of quality requirements need to be met. After understanding the basic situation, you need to provide the appropriate dimensions, size, the required product structures, and the packing method. For special requirements such as openings, shapes, etc., you need to provide accurate CAD drawings.

Q2: Do you support ODM and OEM Service?

We support ODM and OEM production, you only need to provide your design drawings and corresponding CAD drawings, we will try to cooperate with your production!

Q3:How about sample and charge?

A3: It depends on the dimension and requirement of the sample. Normally, the small sample is 100mm*100mm or 300mm*300mm. The general production of samples is required 5-10 working days, depending on the specific requirements of the samples.

Q4: What about the payment?

A4:Normally, we can accept cash, TT and L/C.

Q5: How many products and how many pieces of products can you typically hold?

A5: Generally speaking, glass is very heavy, so generally need to consider the weight factor, the exact amount to be loaded to the actual size and quantity to confirm. It is recommended that customers ship with other light supporting products.

Q6: What's the lead time for regular order?

A6:Typically, for the glass product, the delivery time is 15-30 working days, depending on the ease of processing the goods, whether the company currently has stock, and whether other services are required.